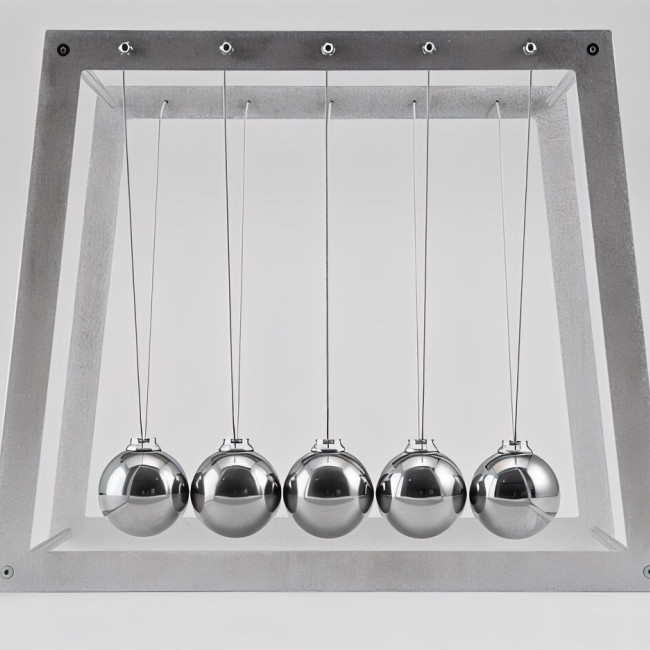

Giant Newtons Cradle Sculpture

-

$654.77 plus delivery Sold Out

- Ex Tax: $654.77

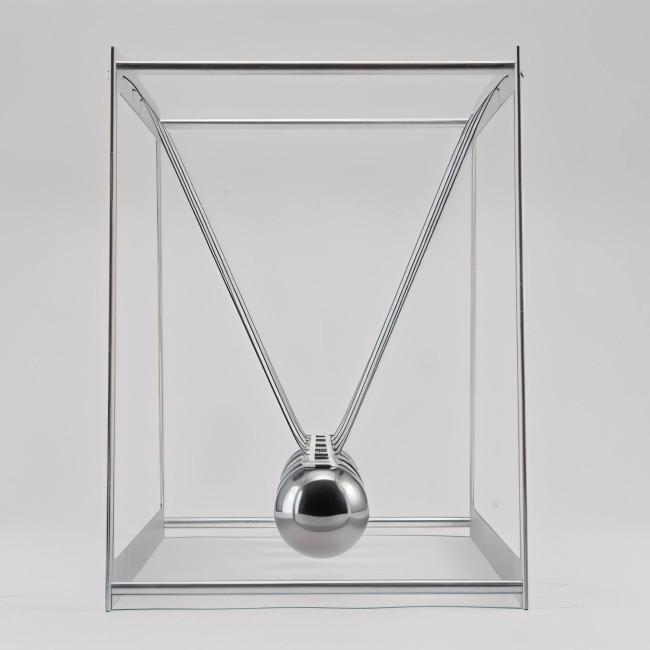

A truly unique (patented in the US) huge Newton's Cradle, machined in the USA with laser precision using aircraft-grade cable and aluminium. Precision parts equal precision swings that are fluid and smooth: each cradle is hand assembled and tuned for optimal motion! Each frame is made with stainless steel and countersink hex socket screws hold the frames tightly to ensure a stable platform.

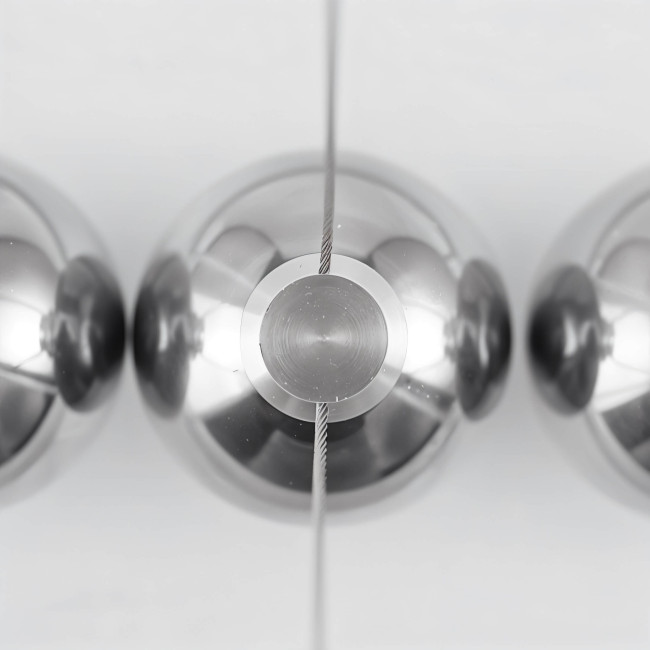

This absolute giant of a Newton's cradle uses 5cm nickel plated chrome steel spheres that weigh over half a kilo each and the junior uses 3.8cm nickel plated chrome steel spheres that weigh about 220g each. Nickel plated chrome steel spheres have exceptional surface quality and high hardness as a result of thorough hardening. Nickel plated chrome steel spheres also offer long life and deformation resistance. Because nickel plated chrome steel spheres possess a hardness rating of 60 on the Rockwell "C" scale, you experience incredible energy transfer when the spheres strike each other. The high percentage of energy transferring then results in longer swing times.

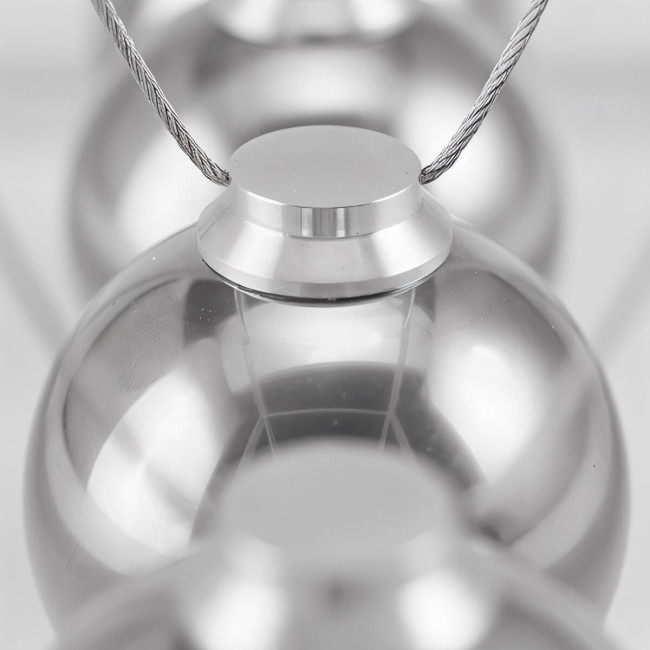

The cables are made with galvanised steel aircraft grade cables, used primarily in aircraft mechanical applications which has a relatively high tensile strength. When used for suspension in the Newton's cradle it provides very minimal transfer of energy thus optimising energy transfer between the spheres. Because of its high tensile strength cable, you can be assured that it will not tangle or break. “6061 t-6 aluminium” is used in the construction of aircraft structures because of its fatigue limit and high tensile strength. By using this aluminium for the frames of the giant Newton’s Cradle they are able to build a solid foundation while making a stunning visual presentation. The caps that attach the cables to the spheres are also made of 6061 T-6 aluminium and affixed using a proprietary application process to ensure that the spheres will never become unattached.

Brand

Giant Newtons Cradle

Frame

Aluminium, stainless steel

Spheres

5cm Nickel Plated Chrome

Size

36 x 32 x 23mm

Weight

5kg

related products

$264.11